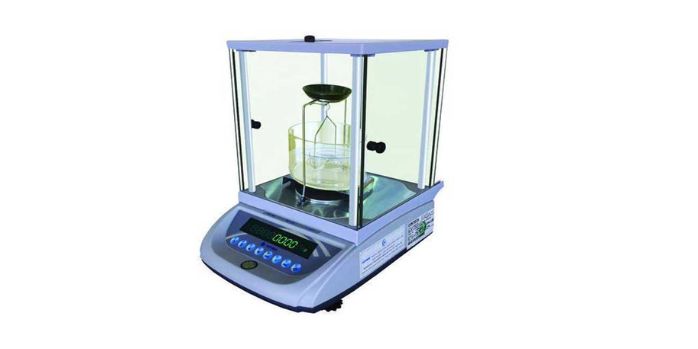

Plastic Density Tester (Specific Gravity Tester) Suppliers

Are you looking for a Plastic Density Tester / Specific Gravity Tester Manufacturer in Navi Mumbai? You have arrived at the right place. We are the best Specific Gravity Tester Apparatus Manufacturer and Supplier in Navi Mumbai, India.

Product Specification

| Accuracy System | Emfc Technology Based High Accuracy System |

| Power Req.: | 90-250V,50/60HZ, 10 Watt, 1 Phase. |

| Display: | LCD Bright Display. |

| Capacity: | 220 Gram. |

| Readability: | 0.001g or 1mg. |

| Repeatability: | 0.001g. |

| Linearity: | 0.001g. |

| Pan Size: | 100mm. |

| Taring Range: | Up to full Capacity. |

| Response Time: | 3 seconds. |

| Operating Temperature: | 15 to 45 Deg C. |

Product Description

Determining material density is a crucial requirement for all polymer companies. It affects the vast majority of its parameters and the caliber of its output. When used with other agents, it improves flow, luster, strength, tensile and modulus properties, and other properties.

Full pails will break when dropped because the material loses flexibility and becomes denser. Choosing a material grade with a higher molecular weight typically increases impact performance without compromising the other aspects of the property.

Accessories With Machine: Adaptor, weighing pan assembly, stainless steel base for beaker, glass beaker, sinker.

Certification: Calibration Certificate With Nabl Traceability For 1 Year.

Warranty: 1-year warranty.

Features

- Accurate calculation of rubber, polymers, and other materials specific gravities.

- High-stability weighing sensor.

- Auto-weighing function.

- The density of the powder improves precision and productivity.

- The technique is easy and practical since the sample is placed on top of the container before being placed in the water container.

Unique Features

IDEAL LAB EQUIPMENTS' high-precision balances use cutting-edge Electro Magnetic Force Compensation (EMFC) technology for unrivaled accuracy and durability. They also have a unique ADC circuit with built-in temperature correction to provide extraordinarily high stability, up to 6 million resolution counts. All adjustment parameters are adjustable and are used to correct minor imbalances between various subassemblies and balances.

Plastic granules OR plastic cutting bits are an example of a raw material density determination kit. One type is intended to be mounted on the pan, while the other is intended to be weighed below the balance.

The density determination kit includes

- A sinker.

- A stainless steel beaker base.

- A glass beaker.

- A density is a weighing pan assembly for analyzing substances with densities less than or more than water.

The remaining activities will be completed by software for automatic density determination (program).

The programmable density of the liquid (other than water) and temperature of the water

In the case of several samples, save all sample weights in the air first, in water, then see the density of individual samples on display one by one.

Advantages

Solid and liquid samples are measured using compact bodies and precise density readings.

Only 10 seconds to assess density and volume by simply immersing the sample in water.

Powder density measurement with 0.001g/cm3 resolution and a reference value of 0.0001g/cm3.

Note: Ideal Lab is the finest Plastic Density Tester Manufacturer and Supplier in Mumbai. We offer Specific Gravity Tester Machines to our clients at a lower price.

What Is A Plastic Density Tester?

Plastic film density is evaluated by immersing test specimens in water and adding isopropanol (or another liquid if sample density exceeds 1 kg/m3) until the plastic sample achieves neutral buoyancy in the solution. The density of plastic films is evaluated by British and International standards ISO 1183.

How Is The Specific Gravity Of Plastic Determined?

The most typical method for determining the thickness of solid plastics is the immersion method, summarized in ASTM D 792 and ISO 1183-1. An evaluation sample is weighed, and its mass is noted in the air. Then, after being submerged in a liquid, its apparent mass is noted. The density and specific gravity are determined using the mass ratio and the liquid density. The immersion liquid is pure water (Method A) or a liquid that is lighter than water (Method B), such as ethanol, IPA, or another chemical.

Why Is The Density Of Plastic Important?

Plastics processors measure productivity in pounds, kilos, or tons of plastic material processed by their manufacturing equipment. Because of this, the bulk densities of various plastic polymers differ. Why is the bulk density of a plastic material important? Bulk density has an impact on material storage.

Why Is Plastic Testing Important?

Chemical testing for polymers and plastics should be necessary to make sure they are suitable for the use for which they are designed. Basic structural data, including molecular weight, distribution, and branching information, are identified through polymer chemical testing.